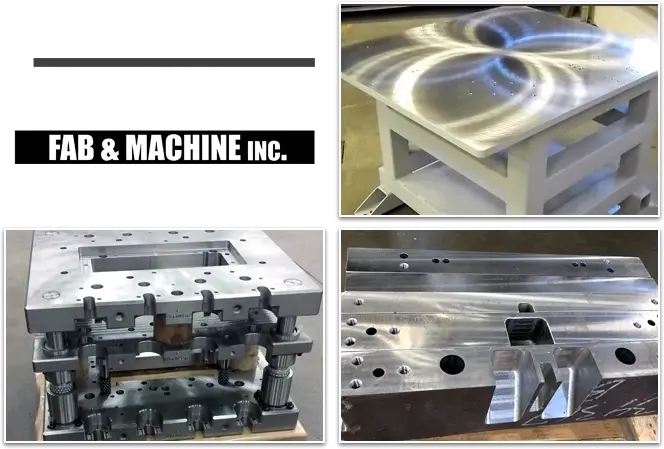

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Straightening?

Straightening is the process of removing stress from a processed piece of steel added during machining.

How It Works

Straightening is typically performed after heat treating and is a necessary step in that process. As steel is processed and machined, it begins to collect stress and will want to curl up based on the amount added. Relieving the steel allows it to “relax” and flatten out.

While steel straightening methods can depend different factors, including the geometry of the part, it’s a necessary process to bring components back to within acceptable tolerances.

BICO Steel’s Straightening Services

A large part of our steel processing services involve stress relief to ensure your product meets its states specifications. To that extent, we feature straightening presses at 400 tons with a maximum width of 120 inches.

We also place an emphasis on quality control with physical, mechanical and ultrasonic testing, and also offer Meta-Lax vibratory stress relief, as well as demagnetizing.

Straightening is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.