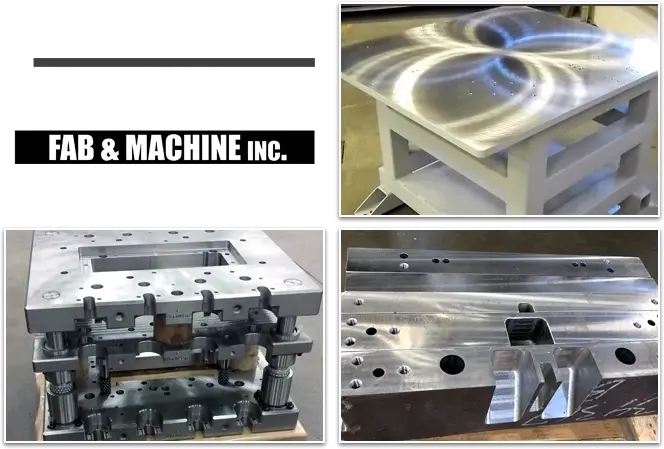

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Surface Grinding?

Surface grinding is a finishing process to refine and smooth a piece of steel. While surface grinders also produce nice, smooth surfaces, they tend to have tighter tolerances when compared to rotary-ground pieces.

Note: Tolerance refers to how close a piece of produced metal is to its stated specs (thickness, parallelism, etc.).

How It Works

Surface grinding moves a grinding wheel or segment in a plane. The grinding wheel contacts the steel and removes material to create a flat surface. The wheel itself is covered in rough particles, which allows it to cut chips of metallic (or non-metallic) substance from a workpiece.

BICO Steel’s Surface Grinding Services

With some of the larger grinders in the area, we’re capable of horizontal surface grinding to 80 inches by 240 inches. Our tolerances are exceptionally tight. When we run indicators on our surface-ground pieces, we expect them to be dead flat.

Surface grinding is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.