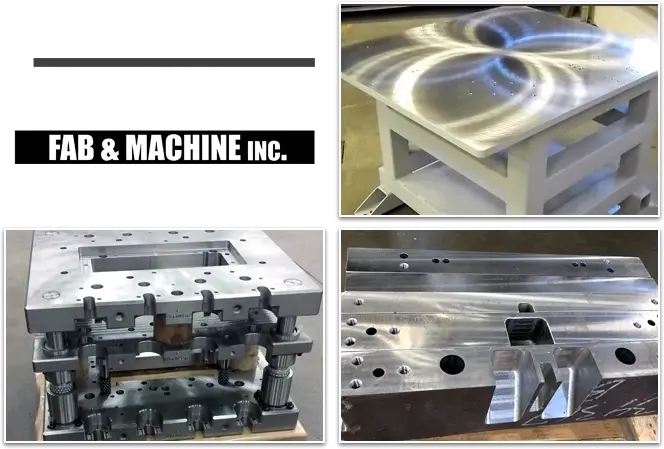

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Plate Milling?

Plate milling is a machining process that uses physical contact to remove unwanted material from a piece of steel. The type of cutting tool needed for this process is what separates it from edge milling.

How It Works

Overall, plate milling works the same as edge milling.

Milling machines feature cutting blades that rotate while they press against a secured workpiece. During operation, the cutting tool moves across the steel and scrapes material off during each pass. Different results can be achieved depending on the type of machine and cutting tool used, but milling generally falls into two categories:

- Face Milling: This type of milling is used when it’s necessary to cut flat surfaces, or faces into steel, or cut flat-bottomed cavities.

- Peripheral Milling: This type of milling is best used when an application requires items such as deep slots, threads and gear teeth to be cut.

BICO Steel’s Plate Milling Services

We understand milling can be viewed as a lower-level machining operation, but that’s where BICO’s value add comes into play. One-stop services allow us to handle your plate milling so you avoid spending valuable machine time on the operation yourself.

We feature larger planer mills that run up to 120 inches by 240 inches. Let us save your equipment some undue stress so it’s ready when you need it most.

Plate Milling is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.