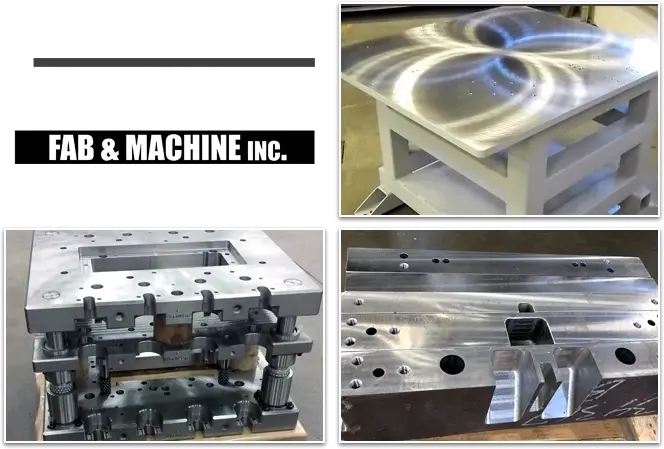

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Rotary Grinding?

Rotary grinding is a finishing process to refine and smooth a piece of steel. Unlike surface grinding, rotary grinders produce a beautiful rotary pattern, though the tolerance isn’t as tight as a surface ground piece.

Note: Tolerance refers to how close a piece of produced metal is to its stated specs (thickness, parallelism, etc.).

How It Works

Rotary grinding is highly productive given how much of the grinding wheel contacts the surface area of the steel being refined. For each table rotation, the entire surface to be ground comes in contact with the grinding wheel.

BICO Steel’s Rotary Grinding Services

With some of the larger grinders in the area, we’re capable of rotary grinding to a 156-inch diagonal with tight tolerances.

Rotary grinding is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.