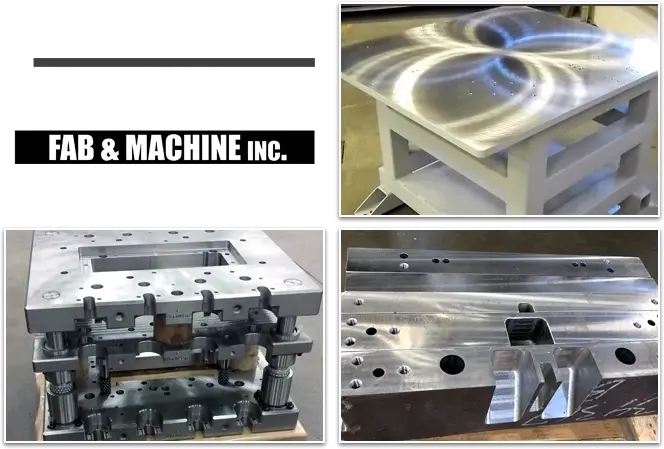

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Heat Treating?

Heat Treating is a process where steel is heated and cooled under tight controls to improve its properties, performance and durability. It can soften metal to improve formability or make parts harder to improve strength.

How It Works

Basic heat treating processes typically have three steps. Steel is heated to a specified temperature and held there for a specific amount of time (this is dependent on the end-use application). When ready, it’s cooled according to prescribed methods based on the material.

Heat treating adds a tremendous amount of value to our products by giving our steel specific properties required for parts to function successfully.

BICO Steel’s Heat Treating Services

Heat treated parts are essential to the operation of items across numerous, crucial industries, such as automobiles, aircraft, spacecraft, computers and heavy equipment of all kinds. This simple process can extend a component’s life span significantly.

We have a number of furnaces to meet your heat treating needs. They can be used for stress relieving, annealing and pre-hardening pieces up to 72 inches high, 96 inches wide and 190 inches long.

Heat Treating is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.