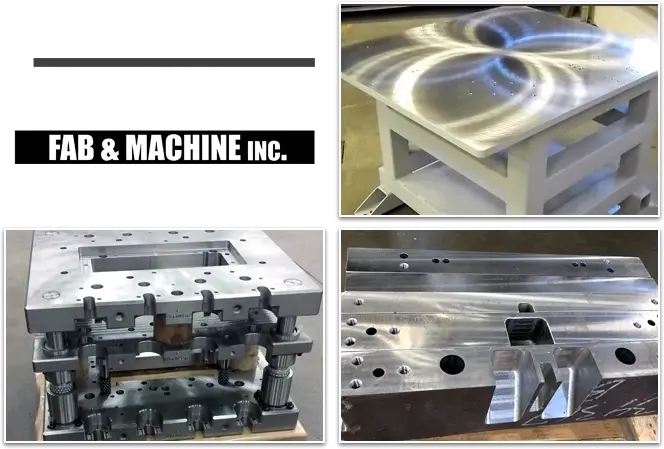

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Eyebolt Drilling?

Eyebolt drilling is the process of drilling holes into a steel plate so it can be lifted and moved easily by heavy machinery. These holes are also referred to as “handling holes.”

How It Works

Properly positioning eyebolts and handling holes is an essential aspect of custom steel processing. Even when providing designs produced using computer software, it’s important to consider how the fabrication process impacts performance.

Placing a hole too close to a workpiece’s edge or bend radius can affect its durability, appearance and function. Proper hole positioning helps ensure a smooth fabrication process and a final product that performs as expected.

BICO Steel’s Eyebolt Drilling Services

BICO Steel has a considerable amount of experience managing precise hole positioning and drilling. We’ll make sure your processed piece exactly matches your design while considering its functional intentions.

Drilling eyebolts is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.