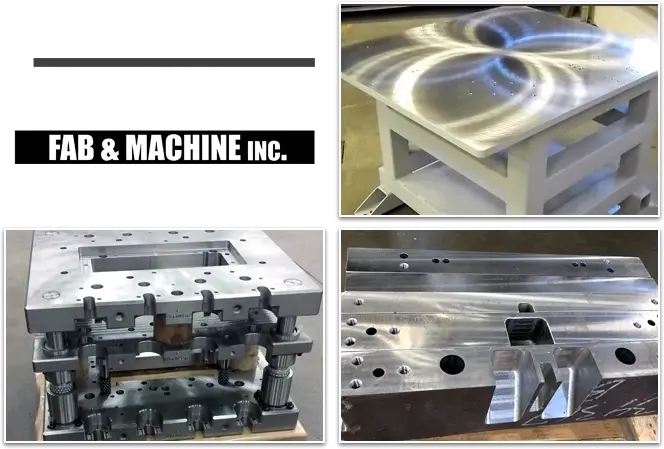

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Plasma Cutting?

Plasma cutting is a thermal cutting and melting process. Unlike flame cutting, it uses an electrical arc to ionize and heat gas to form the plasma used to cut steel.

How It Works

A tungsten electrode is used to create an electrical arc at the plasma cutting torch, and the steel being worked with becomes part of the circuit courtesy of a grounding clamp. Once the plasma is ionized by the electrode, it superheats (to over 36,000° Fahrenheit) and interacts with the steel. This jet of superheated plasma gas severs the steel and blows away any molten metal.

BICO Steel’s Plasma Cutting Services

Plasma cutting is a newer service we bring to the table. Our state-of-the-art machine with five-axis plasma allows us to perform a number of different operations, and is great for making high-quality cuts and fabricating smaller pieces.

Plasma cutting is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.

Plasma cutting is a newer service we bring to the table. Our state-of-the-art machine with five-axis plasma allows us to perform a number of different operations, and is great for making high-quality cuts and fabricating smaller pieces.

Plasma cutting is a newer service we bring to the table. Our state-of-the-art machine with five-axis plasma allows us to perform a number of different operations, and is great for making high-quality cuts and fabricating smaller pieces.