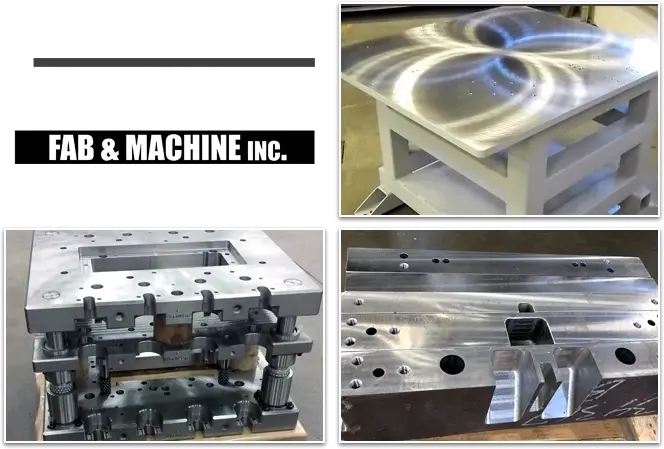

We're proud to welcome Integrity Fab & Machine, Inc. into the BICO Steel fold. Their expertise in die sets, custom fabrications, machined plates, and parallels allows us to offer a higher level of value-added processing than ever before. Check out their website ifabm.com and feel free to reach out to us through your normal BICO channels for more information!

What Is Flame Cutting?

Flame cutting (also known as oxyfuel cutting) is a thermal cutting process using oxygen and a fuel source to create a flame with enough energy to melt and sever steel.

How It Works

To start, a neutral flame heats the steel up to its kindling temperature. Once this is reached, an additional high-flowing stream of oxygen is added to the flame and rapid oxidation takes place. Molten material is removed by gas pressure.

BICO Steel’s Flame Cutting Services

Our flame cutting services allow us to accurately produce complex shapes from steel plates and blocks up to 32 inches thick. We also offer:

- CNC precision burns

- Multi-plane burns

- The ability to flame cut pre-hardened alloy plate

Flame cutting is just one of the many processes we offer in-house. Contact our qualified team for a free, no-obligation consultation and learn about the many benefits you’ll experience working with the only company that can provide both steel plate and forged block processing.